Cement is the most widely consumed commodity after water. It is the main component in the construction and production of infrastructures for building and development of residential buildings, public buildings, and water and sewage systems

Cement is the most widely consumed commodity after water. It is the main component in the construction and production of infrastructures for building and development of residential buildings, public buildings, and water and sewage systems.

Due to its importance and properties, most countries manufacture their own cement locally.

Raw material = a combination of limestone and clay.

Clinker = a new material which is the product of a chemical process of baking the raw material in a kiln at extremely high temperatures.

Cement = ground clinker with added gypsum and minerals.

Concrete = cement mixed with gravel, coarse sand and water, which turns into a building material second to none in terms of convenience, speed of application and strength.

Reinforced concrete = a composite material, obtained by adding steel meshes or rods or other elastic materials to the concrete. This is an extremely strong material, and due to its capacity to resist different types of stress it plays a key role in the construction of buildings. Another factor behind the successful combination of these two materials – concrete and steel – is their almost identical thermal expansion coefficients. As a result, when a reinforced concrete component undergoes a drastic change of temperature, there are no warping or cracks. Concrete also protects the steel against corrosion. In Israel, reinforced concrete is the main building material for residential, commercial and industrial buildings.

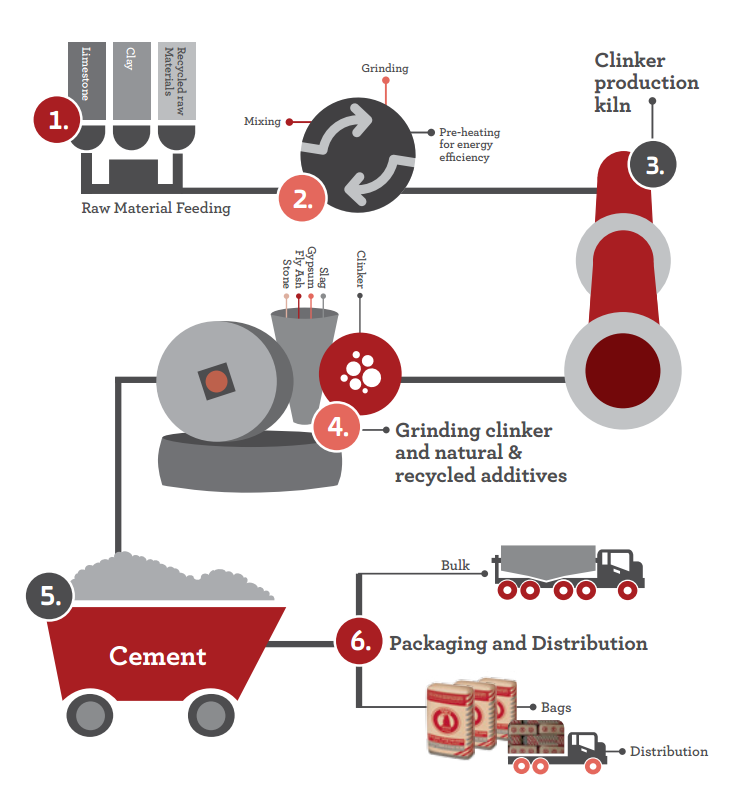

Cement manufacturing process

The process of manufacturing cement begins with the quarrying of the raw materials – rock and clay. Following processing and chemical tests, the raw materials are placed in a kiln. Here the manufacturing process of clinker – an intermediate product used for the production of cement – takes place at a temperature of about 1,600 degrees Centigrade, which is about one third of the temperature on the sun. The clinker is then ground into a fine powder, and when blended with additional materials it produces cement.

There are three common methods for manufacturing cement: the wet process, which is the oldest traditional method; the semi-dry method; and the dry method. The main difference between these methods is the amounts of water added to the raw materials prior to entering the kiln. The less water used, the greater the energy efficiency and thus the cleaner and healthier the environment. Nesher currently owns two dry production lines at the Ramla plant, and production using the wet method, which causes considerable environmental pollution, has been discontinued altogether.

Nesher constantly evaluates and integrates new methods and the use of recycled materials in its efforts to increase the efficiency of its manufacturing processes in regards to environmental impacts; this is based on a sense of responsibility and commitment to the environment and and transparency vis-a-vis the public and stakeholders. The Company was awarded a UN award for its achievements in the area of environmental improvements. In 2014, Nesher became the first Israeli company to publish Environmental Product Declarations (EPDs) at the international EPD organization.